Vectorply debuts Digital Innovation Zone at CAMX

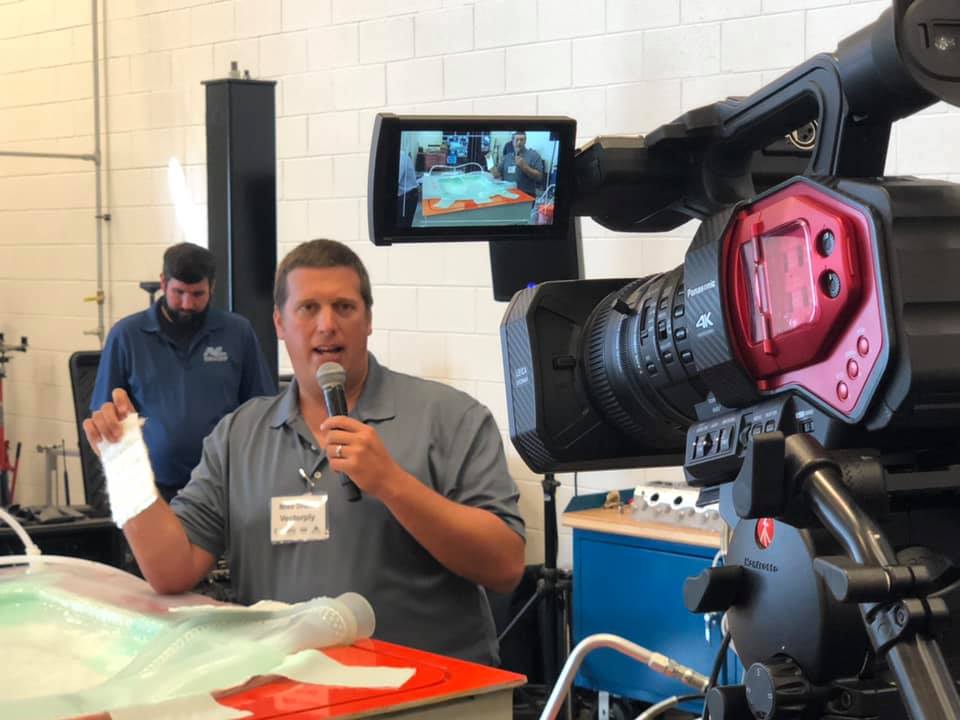

Phenix City, AL – On the opening day of the 2021 Composites and Advanced Materials Expo (CAMX) in Dallas, Vectorply released a new online composite knowledge center in the form of the Digital Innovation Zone hosted at Vectorply.com. Visitors to the new Digital Innovation Zone can browse a diverse library of video resources built to educate and assist anyone currently using or interested in composite materials.

Vectorply’s Digital Innovation Zone features several company-specific informational assets such as a series of tutorial videos for VectorLam, the company’s proprietary laminate design and analysis software. Videos give a complete demonstration of how to get started using the complementary software, as well as more detailed tutorials that address the most frequently asked questions and dive into specific functionalities.

Product highlight videos explain the benefits of different types of Vectorply materials, and lab capability videos detail the wide range of testing services that the company offers. Visitors are also able to learn more from customers who have utilized Vectorply’s products and technical services to gain a competitive edge in their market.

In addition, visitors can learn more about composite materials in general. Users can gain knowledge about the benefits of composite materials through educational videos about fiber types, architectures, and multi-layer products with different backings, cores, and veils. Vectorply’s Digital Innovation Zone is a valuable asset for anyone interested in composite materials or production.

To visit the Digital Innovation Zone, click HERE

Shem Roose

Shem Roose