Introduction

Glass Fiber: E-glass

E-glass (“Electrical” grade glass) is by far the most used fiber in reinforced plastic composites. In many industries, it represents over 90% of the reinforcements used. Its main advantages are:

The main disadvantages are:

- Low modulus (relative to other reinforcing fibers)

- Low fatigue resistance (relative to carbon fibers)

- High weight (relative to other reinforcing fibers)

- Highly abrasive when machined

- Susceptibility to stress corrosion

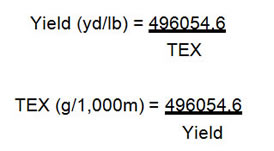

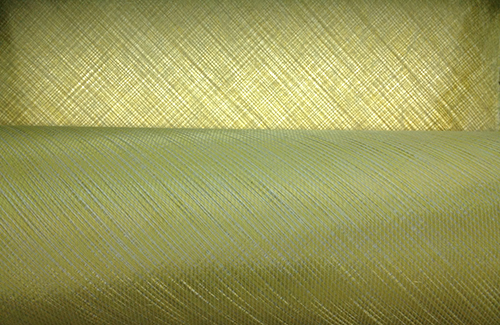

Because of its widespread use, the advantages have a tendency to outweigh the disadvantages. Almost all glass fibers are sold in strands of grouped fibers, or rovings, associated with a particular yield. The yield is the number of yards of roving per pound. The metric unit of measure is TEX which is the weight in grams per kilometer (1,000 meters). The equation for conversion between TEX and yield (YPP) is:

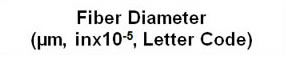

For stitch bonded reinforcement fabrics, typical roving sizes used range from 1800 to 113 yield (276 to 4390 TEX). Some common glass yields and filament diameters are given in table below:

|

|

|

| 4400 | 113 | 24, 94, T |

| 2400 | 206 | 17, 67, MN |

| 1100 | 450 | 17, 67, MN |

| 735 | 675 | 13, 51, K |

| 276 | 1800 | 13, 51, K |

The diameter of the individual filaments can be important because it represents the ratio of surface area of the fiber to its volume. Smaller filament diameters give higher surface area to volume ratios, which means there is more area for resin to bond to. Smaller filaments may give slightly better properties in some instances.

Glass Fiber: E-CR glass

E-CR glass (“Electrical” grade “Corrosion Resistant” glass) is a subset of E-glass fiber which is more resistant to degradation in highly acidic environments. The main difference between E and E-CR glass is the elimination of boron oxide (B2O3) from the base formulation. This difference has lead E-CR glass to be typically called “boron-free glass”, and can be found to be specified in many composite corrosion applications such as cured-in-place pipe (CIPP) and chemical storage tanks & pipes.

Glass Fiber: S-glass

S-Glass (high “Strength” glass) is an improved glass fiber for use in more structurally demanding applications. It has significantly higher strength and moderately higher stiffness than standard E-glass fiber. The density of S-glass is slightly lower than E-glass (2.49g/cc vs. 2.54g/cc), subsequently you can expect a laminate that is 20-35% lighter than the equivalent made from E-glass fiber. S-2 glass (and now S-1) is a commercial version of S-glass made with less stringent non-military specifications, but its properties are similar. There are other variations of high strength glass fiber such as basalt (also known as R-glass) available as well which all attempt to produce equivalent S-glass properties at a lower cost.

Aramid

Aramid fibers are highly crystalline aromatic polyamide manufactured by extruding an acidic solution of a proprietary precursor. Aramid fibers have very low density and high specific tensile strength when compared to commonly available reinforcing fibers. They are best known for their use in bullet proof vests, chainsaw pants, safety gloves and other applications where cut resistance and damage tolerance are required. The main advantages of aramid fibers are:

Light weight

Light weight- High impact damage tolerance

- High tensile strength

- Moderately high tensile modulus (midway between E-glass & HS carbon)

- Excellent vibration damping

- Low (negative) longitudinal thermal expansion

The main disadvantages of aramid are:

- Very low compressive strength

- Susceptibility to UV radiation

- Difficult to machine

- High moisture absorption

- Very high transverse thermal expansion

Aramid fibers are often used in combination with other fiber types. This allows the designer to take advantage of their unique properties and low weight, while avoiding the drawbacks. Aramid fibers are sold in untwisted tows by denier ( g / 9,000 m ), which is related to yield or tex by the following equations:

Carbon Fiber

Carbon fiber has been increasingly utilized in high-performance applications such as aerospace, sporting goods, marine, and infrastructure over the past several decades. The combination of excellent stiffness, strength, fatigue resistance, and light weight make it the ideal reinforcing fiber for high-performance composites.

Properties

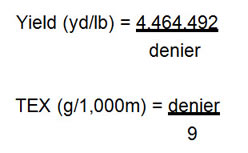

Compared to all other current commercially available reinforcing fibers, carbon fiber provides the greatest specific modulus and specific strength (modulus and/or strength divided by fiber density) as well as the largest range of these properties.

Other properties such as high fatigue resistance, thermal and electrical conductivity, and low thermal expansion allow carbon fiber to be used in applications where standard E-glass or aramids can not. Multiaxial reinforcements like VectorUltra™, allow for these unique properties to be tailored to any application’s specific need.

Types of PAN Based Carbon Fiber

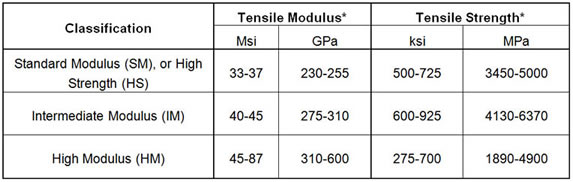

PAN Based: The most widely available and utilized type of carbon fiber, is produced from a specially formulated polyacrylonitrile (PAN) precursor fiber. The PAN carbon fiber is generally classed in 3 different groups according to modulus:

*Note: Carbon fiber modulus, strength, and elongation to beak are ideal values produced via impregnated strand testing and may not translate directly to the corresponding fabric/composite properties due to fiber misalignment, resin compatibility, and damage during processing.

Standard Modulus (SM) or High Strength (HS) carbon fiber is the most widely used and economical fiber for industrial applications such as marine, wind energy, and transportation. This type of fiber gets its name from the early years of carbon fiber, when tensile strengths became greatly reduced when modulus was increased. During this time, tensile strengths for standard modulus fiber peaked out around 500ksi (3450 MPa), while the high modulus fibers were much lower, around 275 ksi (1890 MPa). The HS carbon fibers still have some of the highest strength values of all industrial grade reinforcing fibers, as well as moduli around 3 times that of standard E-glass. The relatively high elongation to failure (1.5-2.0% ideal fiber values) of the HS carbon fibers also allow them to be used in highly dynamic applications such as yacht hulls, softball bats, and jet engine blade containment cases.

Intermediate Modulus (IM) fibers were developed for high performance aerospace applications which required both higher strength and modulus than the standard HS carbon fibers. While still mainly used for aerospace, IM carbon fibers are also being utilized in high performance pressure vessels, sailboat spars, and other more industrial applications where performance outweighs price.

High Modulus (HM) fibers have been typically used in high end sporting goods and space structures where the high stiffness and low to zero thermal expansion provide optimum weight and performance. Typically, as the modulus is increased, the strength is reduced due to increased crystallization of the fiber. Over the years, developments have been made to increase the strength of HM fibers, decrease their brittleness (ideal fiber elongation to failure is still around 0.5-1.4%), and increase their usage. As the modulus increases, so does the price, making HM fibers the most expensive and least produced PAN based carbon fiber. IM and HM carbon fibers are smaller in diameter than HS fiber (5 µm and 7µm respectively) which produces a finer yield or TEX value for the same tow size.

Tow Size

The number of filaments per yarn of carbon fiber is denoted as its tow size. The tow size is generally given in terms of “K”, or thousands of filaments. Standard tow sizes range from 1K (1,000 filaments) up to 48K (48,000 filaments) and sometimes higher. Most aerospace applications utilize small tow carbon such as 3K and 6K, while more industrial applications use 12K, 24K, and 48K tows. Generally, smaller tow sizes produce lighter areal weight fabrics with good coverage, while larger tows produce heavier weight fabrics. Smaller tows sizes also cost more to produce than larger tows (less material being produced per given process set-up), and are subsequently more expensive.