Vectorply highlights VectorUltra line at CAMX, IBEX

Phenix City, Ala. – Each year Vectorply Corporation exhibits at the Composites and Advanced Materials Expo (CAMX) and the International Boatbuilders’ Exhibition & Conference (IBEX). This year the focus at both shows was their expanding advanced composite reinforcement line of VectorUltra products.

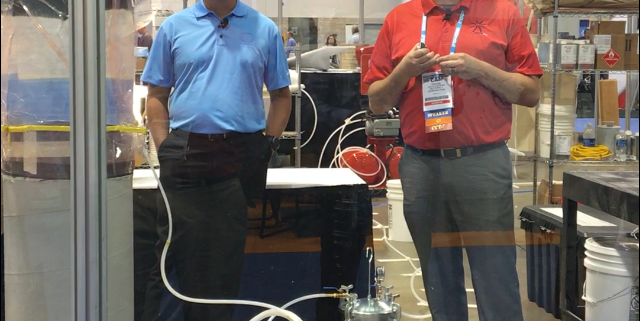

At CAMX in Anaheim, CA Vectorply Director of Composites Engineering Trevor Gundberg, P.E. and Field Engineer Mike Ditzler participated in live demonstrations at Composites One’s Lean Mean Process Machine. Gundberg assisted in the Infrastructure Repair demo while Ditzler helped with the New Tooling Technology and Consumer Recreation demos.

During the Infrastructure Repair demo a mock concrete column was repaired using a combination of Vectorply’s E-LT 2900 and C-LA 1812. The presentation demonstrated how to use vacuum bag infusion in the field to repair damaged columns and provide added stability for seismic protection.

In the New Tooling Technology demo Ditzler helped demonstrate an infusion for an Indy Car intake scoop. The Consumer Recreation demo featured skateboard production through the use of silicone bag molding. Vectorply’s toughened carbon, C-BXi 0456, was used to increase impact resistance and damage tolerance and carbon/Innegra hybrid CI-TTXCX 1310 and C-WVs 0600-TW were also used during the demos.

With CAMX in the books, Vectorply’s team made the cross-country trip to exhibit at IBEX the following week in Tampa, FL. Vectorply also participated in an eye-catching exhibit at IBEX aimed at highlighting the future of composites production.

The “Future Materials Exhibit” is a hands-on display that is presented by Professional BoatBuilder and CompositesWorld magazines. In the exhibit, Vectorply highlighted two special VectorUltra products, C-BXi 0456 and C-4QX 9400, and a comingled E-glass/polypropylene thermoply product, EPP-W 2200.

EPP-W 2200 is a 22oz. fabric that offers users a wide range of flexibility due to the combination of thermoplastic and thermoset fibers. An 11’ 4” Super Cruiser stand up paddle board produced by Bounce Composites provided a great example of an end-use application for the thermoply product and received a lot of attention from visitors.

Panels of the two carbon products were also on display in the exhibit. The balanced and symmetric construction (mirror image) of the carbon C-4QX 9400 enables fast build-up of thick sections along with very low and consistent CTE and uncoupled (no potato chipping) laminates. The toughened C-BXi 0456 with interleaved lightweight polyamide veils provides greater interlaminar toughness and reduces delamination/damage zone size in the event of an impact.