POSITION FILLED – Naval Architect / Composite Engineer Job Opening

/in Uncategorized /by ScottVectorply Corporation, a world leader in the manufacture and distribution of composite reinforcement fabrics, has an immediate opening at its Phenix City, AL location for an experienced Naval Architect and/or Composite Engineer.

Primary Responsibilities

- Provide laminate recommendations for potential and current customers utilizing Vectorply reinforcements and VectorLam software

- Provide technical service and support to Vectorply sales / customer service staff, and customer base regarding Vectorply reinforcements and VectorLam software

- Manage VectorLam software development and updates

- Perform /arrange laminate testing (physical or mechanical) in support of customer and internal projects

- Conduct presentations regarding Vectorply reinforcements at conventions or to small groups of customers

- Submit technical papers to industry publications

Additional Responsibilities

- Assist in design of new reinforcement fabrics for specific applications

- Assist with the technical and aesthetic aspects of new marketing literature

Qualifications/Requirements

- Minimum Bachelor’s Degree in Engineering – Naval Architecture, Marine, Ocean, Composite, or Mechanical

- At least 5 years experience in structural design with composites materials in marine applications (small and/or light craft) utilizing industry standards such as ISO 12215, DNV HSLC, and ABS HSC

- Proficient knowledge of composite manufacturing processes such as open molding, vacuum infusion, Lite RTM, RTM, vacuum bagging, etc.

- Familiarity with composite material applications in industrial, wind energy, & sporting goods industries

- Proficiency in some form of CAD (Rhino, SolidWorks, AutoCAD, etc.) and FEA (Strand7, HyperMesh, etc.) software. Experience with programming languages (SQL, Visual Basic, etc.) is highly beneficial

- Up to 25% travel generally within the US and Canada

- Excellent written and verbal communication and interpersonal skills with public speaking opportunities

- Reside within the Phenix City, AL / Columbus, GA area with an office located at the main plant

- Experience with quality systems (ISO 9001, AS9100, etc.) is beneficial

Interested qualified applicants are encouraged to email their resumes to employ@vectorply.com with the heading “Naval Architect / Composite Engineering Position”.

Infusion success starts with Vectorply’s “R2O”

/in Uncategorized /by ScottVectorply’s “Road to Optimization” crucial in Cruisers Yachts 390 Express Coupe infusion

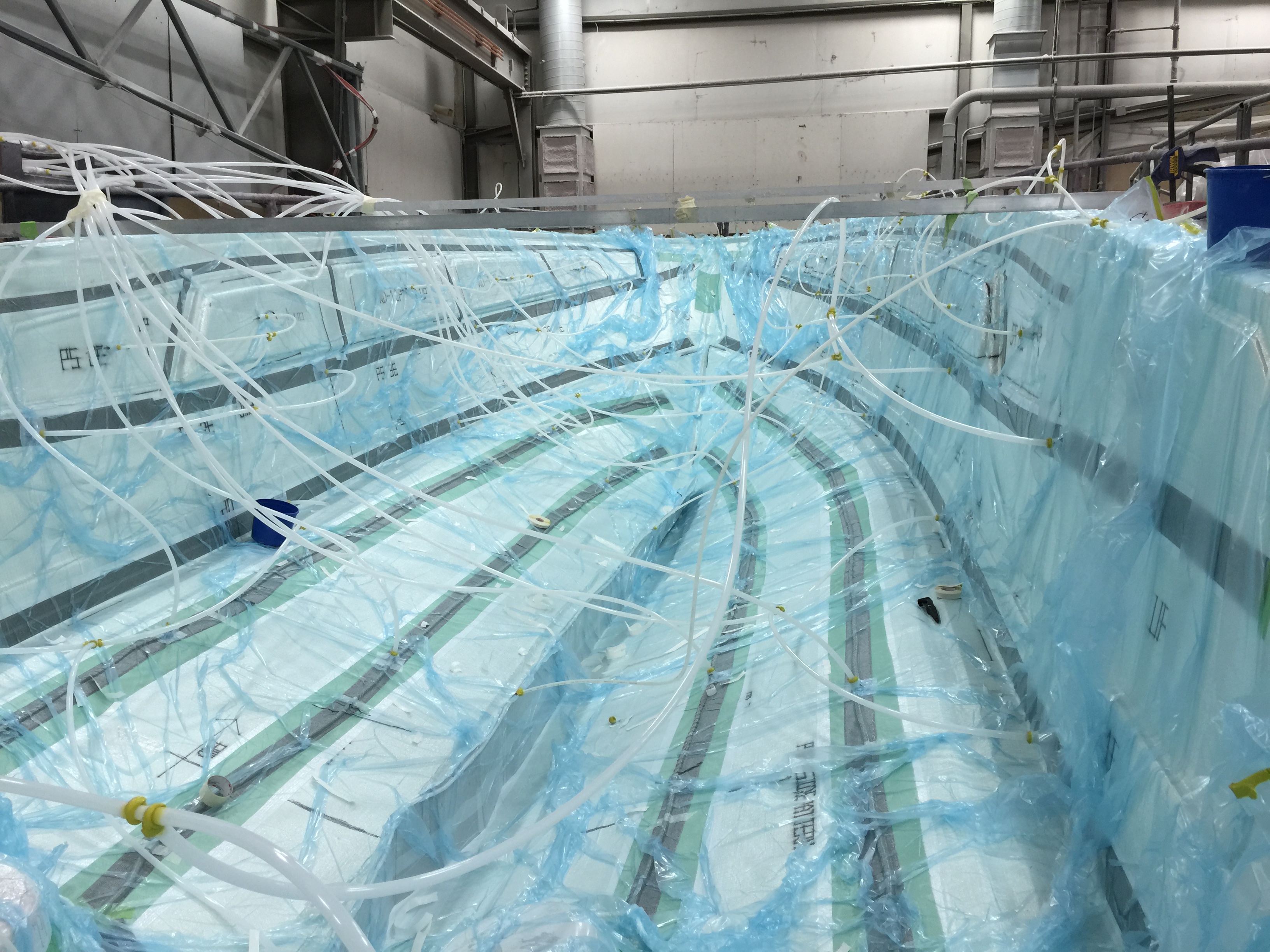

PHENIX CITY, Ala. – Making the switch from open molding to vacuum infusion can be a daunting challenge, particularly when the first large part to be infused is a newly designed 39’ boat hull. In order to help transition their new 390 Express Coupe to infusion, KCS International, manufacturer of Cruisers Yachts, enlisted the help of Vectorply’s Engineering Services Team.

Vectorply employs four full-time engineers to help lead customers down the Road to Optimization (R20) where the goal is to optimize customer’s workflow from initial audits, part and laminate design, to material selection and processing.

The work began before the hull mold, which was split down the middle due to complex geometry and to reduce major repair hours, was even delivered. The hull bottom and sides were analyzed using the requirements outlined in ISO 12215 with Vectorply’s VectorLam software. VectorLam is an Excel-based classical laminate theory (CLT) analysis program that allows users to compare laminates, design plates and stiffeners, as well as analyze hull scantlings using requirements from ISO 12215 and DNV High Speed, Light Craft and Naval Surface Craft.

Once initial laminates were developed, a team consisting of Vectorply, Composites One, 3A Composites (Baltek) and CCP assembled to produce test panels to verify resin flow characteristics and mechanical properties as well as surface cosmetics. Multiple iterations of test panels were made which included changes in reinforcement fabrics, core materials, resins, barrier coats, and catalysts in order to meet Cruisers’ surface cosmetic requirements.

The final hull side and bottom laminates utilized Vectorply’s E-QXM 3515, which is a 35 oz/yd2 quad-axial fabric with a 1.5 oz/ft2 chopped strand mat attached. Also utilized were balsa core and Lantor Soric products from 3A Composites as well as gelcoat and resins from CCP. Fabric and core materials were all kit cut by Mahogany Company.

The surface profile of the chosen infusion laminate schedule rivals most open mold laminates with quality and consistency unattainable in traditional open molding. Staff from Vectorply, Composites One, 3A Composites, CCP and Mahogany were all on-site for the infusion of the first hull to provide training to Cruisers employees and demonstrate best practices. The results of the switch from open molding to infusion were easy to see. Cruisers was able to reduce the finished hull weight by over 800 pounds, and they also reduced layup time from 6 days to 4 days, all while improving laminate quality and consistency.

Why not let the Vectorply Engineering Services Team lead you and your next project down the Road to Optimization!

Boeing recognizes Vectorply with Certificate of Appreciation

/in Uncategorized /by ScottPHENIX CITY, Ala. – Vectorply’s National Sales Meeting got off to an exciting start as Co-President Trey Sawtelle presented a Certificate of Appreciation from The Boeing Company to the Vectorply team. The certificate recognized Vectorply for ‘Outstanding performance in the development and advancement of multi-axial non-crimp fabric technology that will enable next generation composite structures’.

Boeing is the world’s largest aerospace company and leading manufacturer of commercial jetliners and defense, space and security systems. A top U.S. exporter, the company supports airlines and U.S. and allied government customers in 150 countries.

Vectorply awarded IBBI’s Outstanding Partner Award

/in Uncategorized /by ScottPHENIX CITY, Ala. – Vectorply would like to thank the members of the IBBI (Independent Boat Builders, Inc.) for awarding our company the Outstanding Partner Award for 2014.

Independent Boat Builders, Inc. is a collaborative effort to negotiate the best sources and arrangements for raw materials. It’s a purchasing cooperative founded by a group of independent boat builders who are continually looking for ways to add value to their businesses.

We are honored to receive this award from such a tremendous organization!

Vectorply Corporation expands Field Engineering staff

/in Uncategorized /by ScottPhenix City, AL – February 17, 2015 – Vectorply is proud to announce the promotion of Mike Ditzler to Field Engineer.

Mike has played a key role in many recent successes in the field. His knowledge and experience with many different composite materials and processes translates to instant value for our customers. Mike will take on a broader role managing larger, long-term engineering projects. This includes leading customer s down Vectorply’s “Road to Optimization” where the goal is to optimize customer’s workflow from initial audits, part and laminate design to material selection and processing.

Trey Sawtelle, Co-President of Vectorply says, “This move continues to affirm Vectorply’s commitment to offer the best value-added products, engineering and technical services in the composite reinforcement industry. Each member of the Vectorply team is dedicated to keeping our customers first.

Mr. Ditzler holds a Bachelor of Science degree in Physics & Mathematics from Dickinson College and a Master’s degree in Mechanical Engineering from Florida Atlantic University.

Vectorply Corporation specializes in the development, manufacturing and distribution of composite reinforcement fabrics.

Vectorply Expands Manufacturing Capabilities

/in Uncategorized /by RickPhenix City, AL- Vectorply Corporation is pleased to announce the expansion of its advanced product manufacturing capabilities with the installation of a new Liba Max 5 machine. The state-of-the-art Liba Max 5, is the first machine of its type in North America.

The new Max 5 will expand Vectorply’s domestic capacity for manufacturing multiaxial, spread tow carbon fiber reinforcements. The installation of the Max 5 is Vectorply’s most recent addition to its already broad range of carbon multiaxial fabric capabilities. This new machine has the capability to make some of the lightest weight non-crimp carbon fiber fabrics in the world. The investment was made to support Vectorply’s growing domestic customer base utilizing carbon multiaxial fabrics.

JEC Conference in Paris

/in Uncategorized /by RickTrevor Gundberg, Vectorply’s Director of Composite Engineering, is very excited to be meeting with some of our biggest customers and suppliers at the upcoming JEC Conference in Paris, France! Vectorply continues to be interested in all of the new materials and process technology regarding the advanced composites market. If you are planning to attend and would like to meet with us, please contact Trevor directly at tgundberg@vectorply.com to set up a meeting.

For more information regarding the conference, please see the link below:

http://www.jeccomposites.com/events/jec-europe-2014

Follow us

My TweetsLatest News

Auburn Engineers team up with Vectorply for HERC ChallengeMay 3, 2024 - 8:32 pm

Auburn Engineers team up with Vectorply for HERC ChallengeMay 3, 2024 - 8:32 pmEvery year engineering students worldwide compete in the NASA Human Exploration Rover Challenge (HERC) to design and engineer human-powered rovers. Teams endure a series of challenges from obstacle courses and missions to judges scoring based on design and functionality. The goal of this project is to further interest in scientific exploration and for students to […]